The industrial sector has been undergoing a profound transformation for some time. While many traditional production lines in the past relied on isolated machines and manual processes, today the trend is increasingly moving toward intelligent and interconnected systems. At the core of this transformation is especially the communication between different intelligent devices. This is often referred to as the Industrial Internet of Things (IIoT). Such networking allows machines, software, and sensors to exchange data in real time, making processes more flexible, secure, and efficient.

Real-Time Data as a Driving Force in Industry

Intelligent devices used in industrial production provide the capability to continuously collect and analyse data. For example, sensors installed in machines can measure wear, pressure, or temperature and immediately transmit this important information to central systems and other devices without delay. This allows production personnel to detect problems much more quickly and to perform necessary maintenance in a timely manner, preventing more serious damage.

Processing all relevant real-time data also allows for more precise production planning, minimised downtime, and more efficient use of resources. Companies benefit from higher product quality, and in many cases it is also possible to reduce costs.

Another interesting application area is production planning and production optimisation. By continuously analysing historical and current data, companies can better estimate the materials needed, avoid bottlenecks, and in many cases even reduce inventory levels. When combined with algorithms related to machine learning, production lines can also be adjusted much more dynamically and easily to fluctuations in demand.

Communication Protocols and Platforms in Industry

For smooth and fast communication between different intelligent devices, platforms and standardised protocols are essential. A modern and widely used protocol is MQTT, which was specifically developed for reliable data transmission between networks and devices. Companies in the industrial sector that rely on such an MQTT platform benefit from secure and scalable infrastructures, which can be integrated both into complex industrial systems and into small sensors.

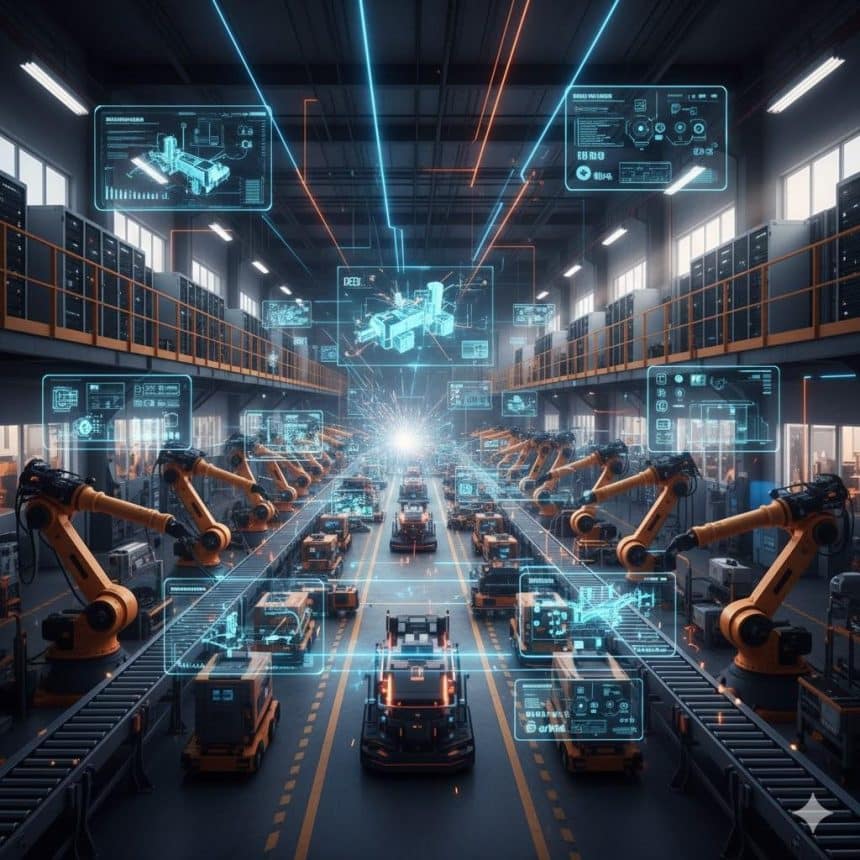

Picture: Intelligent Communication in the future industry

AI-generated with Google Gemini

Such platforms are an important link between analytical tools and devices. They help industries collect, process, and then transform important data streams into understandable and comprehensible information. This allows previously isolated devices to be integrated into a self-managing and intelligent system.

In this context, in addition to MQTT, other protocols such as MATTER, AMQP, OPC, or UA also play an important role. These protocols provide additional management and security functions, which are particularly useful in large industrial facilities.

Artificial Intelligence and Automation

The effects of automation in industry can be further enhanced by integrating Artificial Intelligence (AI) into the communication between intelligent devices. Deployed AI systems are capable of recognising patterns in collected data and making autonomous decisions and predictions in real time.

Combining AI with IIoT also enables predictive maintenance in industrial facilities. Machines are capable of independently reporting when components need to be replaced. This reduces costly and prolonged production stoppages. Intelligent systems are also playing an increasingly important role in quality control. Here, sensors and cameras immediately detect defective products and ensure that they are quickly removed from the further production process.

It is also interesting and advantageous for industrial companies if AI is able to enable dynamic process management. In this case, depending on material availability and workload, certain production orders can be prioritised. This allows existing resources to be used more efficiently and delivery times to be shortened when necessary. These benefits are particularly significant in industries with fluctuating demand and high product variety.

Connected Systems: Data Privacy and Security

With the growing networking of industrial systems, the requirements for data privacy and security naturally increase. When more devices communicate within a network, the risk of unauthorised data access and cyberattacks also rises. That is why it is much more important for industrial companies then for a Smart home to integrate robust and modern security concepts that protect both the transmitted data and the devices themselves.

In this context, issues such as continuous monitoring, access controls, and encryption are becoming increasingly important. At the same time, companies must ensure that all collected data and information comply with the relevant data protection regulations.

Resilience strategies against possible system failures are also becoming increasingly important. After all, the failure of connected devices can bring entire production processes to a halt. Emergency plans, redundant systems, and regular backups are therefore becoming an integral part of modern industrial facilities.

Moreover, resilience strategies against system failures are gaining even more importance. If connected devices fail, entire production processes can be paralysed. Redundant systems, regular backups, and emergency plans are therefore increasingly becoming an essential component of modern industrial facilities.