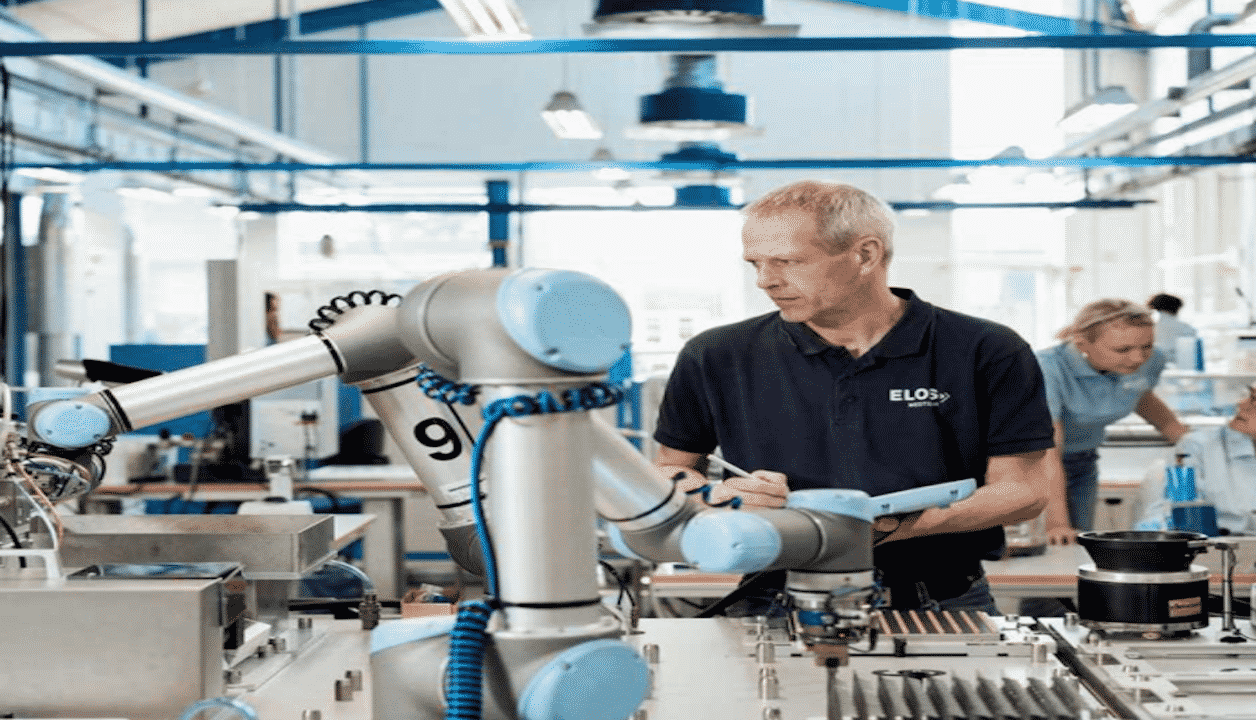

Commercial robots can fully automate the injection molding process by using a unique robot to heap plastic parts into the molding machine. The robot also put the finished products onto the set conveyor belt.

Manually operated injection molding has many rooms for errors, but using robots in the procedure guarantees high-quality products. The items are well-formed, cut, and accurately measured each time.

The use of injection molding robots gives plastic manufacturers a competitive edge, with a significant increase in the parts’ quality and productivity.

To understand how injection molding robots work, you need to know what is injection molding.

What is Injection Moulding?

Plastic injection molding is a production process used for producing plastic commodities in a very high volume. Injection molding happens in assembly-line production, where thousands of identical products are repeatedly made.

As the process is exceptionally repetitive, commercial robots can be deployed to perform the task.

A familiar application of injection molding is tending the injection molding machine. The robot can empty the finished parts from that injection molding machine and place them on the conveyor belt.

In conventional injection molding, this work is tedious. It needs much caution because of the heat-sensitive material used, which poses a significant threat to human workers. By using the injection molding robot, no employee is at risk of getting hurt. The products produced will be uniform and of high quality.

The robot also relieves employees from the highly repetitive task, which can be boring to engage in other complex activities requiring human supervision.

injection molding is used to create many beautiful things.

These things are bottle caps, wire spools, toys, automotive components and parts, pocket combs, storage containers, musical instruments and pieces, small tables, one-piece chairs, mechanical parts, and almost all plastic products we use daily.

After molding and demoulding, plastic parts will not be used directly. The parts need additional treatment. Since the treatment is performed after molding and demolding, it’s known as post-processing, and it takes the following processes:

1) Trimming

After the demolding process, the plastic parts will occasionally have additional materials such as flying edges that can alter the plastic parts’ use and appearance, so it must be removed. Removing these excess materials is simple, and they can be manually removed using easy tools or you can engage a robot.

2) Heat treatment

To make injection mold high quality and accurate, injection molding process must heat the injection mold. It enhances the accuracy of injection molds and also improves the quality of the injection molded parts.

Injection molding robots can also be used to do above process, better known as post process.

Here’s how.

The role of Injection molding robots in Post Processing

Robotics technology has a considerable role to play in plastic injection mold post-processing. The robotic trimming cell gives higher repeatability than a human worker performing similar tasks. It raises the flexibility of performing complex operations.

A robot can continuously dispense a similar amount of adhesives or sealant after a very repeatable pattern, giving significant shot accuracy, reducing waste, and significantly improving the cycle time.

Robots can conveniently pick and place the plastic molded part with or without a vision for additional operations such a testing, hot stamping, and inspection.

In assembling injection molded parts, a robot can perform multiple welding tasks using infrared and ultrasonic, significantly increasing the accuracy and reducing cycle times.

Robots also meet the needs of automated finishing, ranging from PAD printing to polishing.

Moreover, the plastic production line’s final stage can be automated to make a significant production rate and cut down the cost. The robots take over tasks that are highly repetitive and strenuous such as labeling, wrapping, palletizing, and enable more room for superior storage, logistics, and packing.

Wrapping up

The use of injection molding robots is certainly making injection molding an exciting process. They are cost-effective, keep human workers, and boost production by a significant margin. That’s why injection molding producers are turning to them in large numbers.

And we can wait with bated breath to see what’s next in robotic automation. I’m sure something great is still cooking.