Makers today face tighter timelines, higher expectations, and more complex hardware requirements. Automation now supports these pressures in practical ways. Teams use machines to repeat precise tasks that once required constant human oversight. This shift allows builders to focus attention on design quality and testing depth.

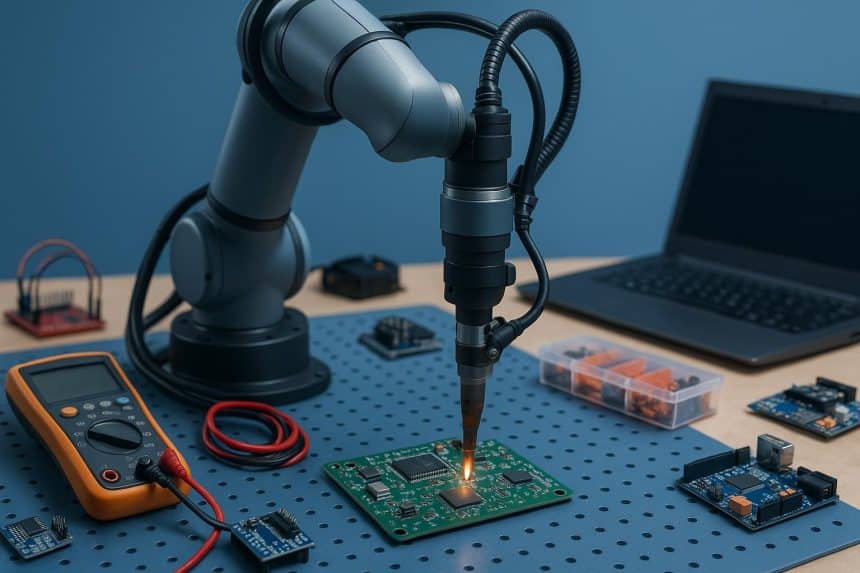

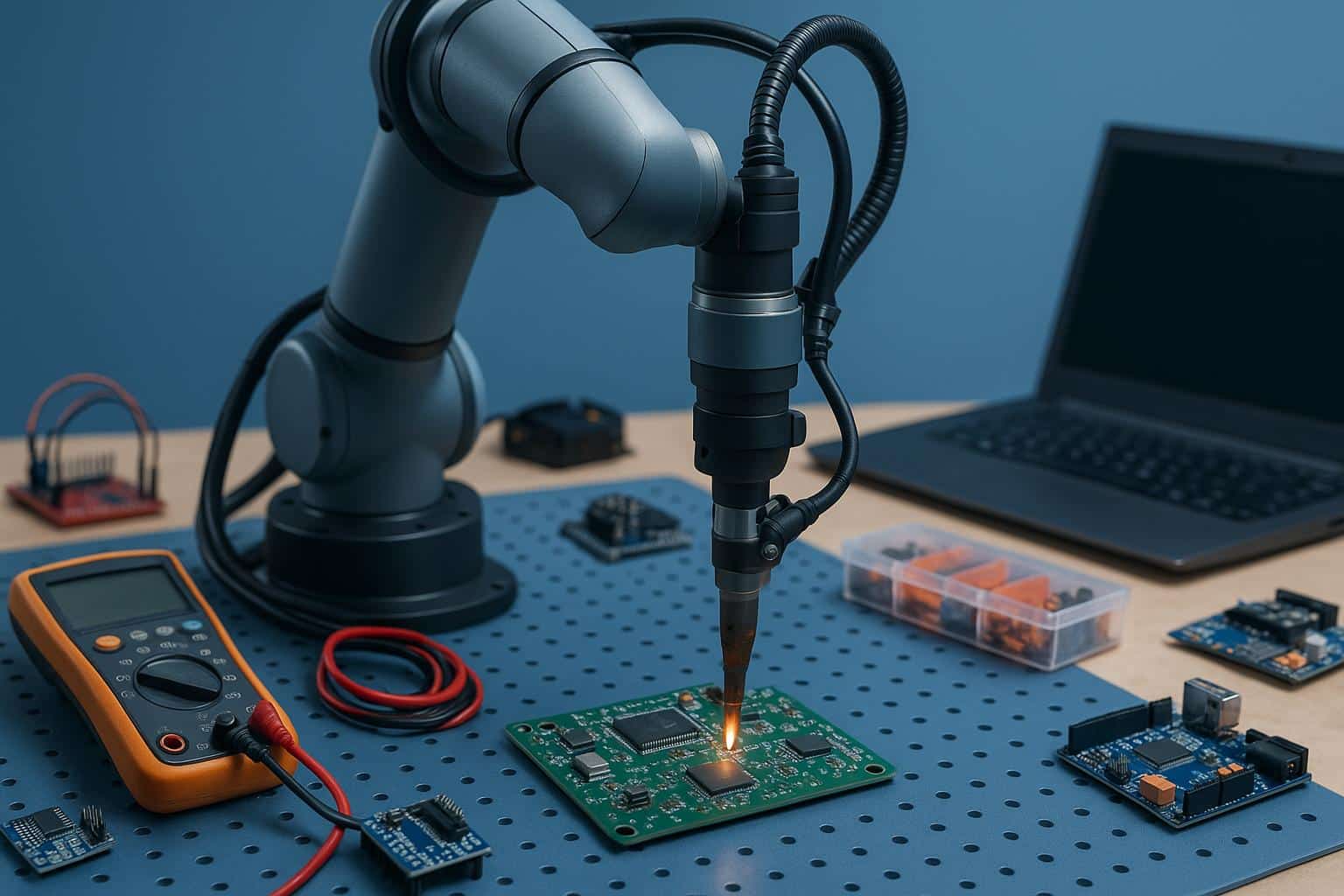

Small workshops now access tools once limited to large factories. Desktop CNC machines, automated soldering arms, and programmable testers appear in garages and shared labs. These tools reduce manual error and speed early iterations. Makers can test more versions without exhausting their teams.

Automation also improves consistency. Machines follow instructions the same way every cycle. That consistency matters during prototyping and early production runs. Hardware teams gain confidence that results reflect design choices instead of human variability.

As automation spreads, maker culture adapts. Builders learn programming alongside fabrication. Documentation improves and processes gain structure without killing creativity. Automation becomes a partner rather than a replacement.

How Automated Fabrication Tools Are Changing Prototyping

Automation changes how makers approach prototypes. Teams no longer treat prototypes as fragile or temporary. Automated tools allow repeatable builds that support real testing.

3D printers create enclosures overnight. Pick and place machines assemble boards with consistent spacing. Automated welding robotics for tech manufacturing now appear in advanced maker spaces and startup labs. These systems handle joints that demand strength and precision.

Automated welding robotics for tech manufacturing help teams test structural components earlier. Makers no longer wait for external fabrication partners. They validate strength, heat tolerance, and alignment in house.

This access shortens feedback loops. Designers spot flaws faster. Engineers adjust tolerances sooner. The prototype phase becomes more data driven. Makers gain clarity before committing to production tooling.

Automation also supports small batch runs. Teams produce ten or fifty units without rebuilding workflows. That flexibility supports pilots, demos, and early customers.

The Role Of Software Automation In Hardware Development

Hardware development relies on more than physical tools. Software automation now coordinates tasks, data, and communication across teams.

Version control systems track design files. Automated test scripts validate firmware changes. Build systems log results without manual entry. These systems reduce missed steps and confusion.

Consultants who support hardware teams also benefit. A digital client management portal for consultants helps manage timelines, feedback, and documentation. Clear records prevent miscommunication during complex builds.

A digital client management portal for consultants centralizes approvals and revisions. Makers spend less time searching email threads. Consultants provide clearer guidance. Projects move forward with fewer delays.

Automation software supports transparency. Teams know what changed and why. New contributors onboard faster. Knowledge stays accessible instead of locked in memory.

How Makers Balance Automation With Hands On Craft

Automation does not remove hands on work. Makers still shape ideas through physical interaction. The balance simply shifts.

Teams use automation for repetition. Humans handle judgment, adjustment, and creative problem solving. Makers tune machines based on tactile feedback and visual inspection. That collaboration improves outcomes.

Workshops design flexible workflows. Automated steps handle routine fabrication. Manual stations handle custom finishing. This mix preserves craftsmanship while improving output quality.

Makers also learn to trust machines gradually. Early runs include close supervision. Teams review results and refine parameters. Confidence builds through experience rather than assumption.

This balance protects maker identity. Builders remain involved at every stage. Automation supports their intent instead of replacing it. The craft evolves without disappearing.

Why Automation Helps Hardware Teams Scale Responsibly

Scaling hardware presents unique challenges. Quality must hold steady while volume increases. Automation provides control during that transition.

Machines follow defined processes. Teams document those processes clearly. Training becomes easier. New staff learn systems faster. Output stays predictable.

Automation also supports compliance and safety. Systems log actions automatically. Teams track material usage and test results. Audits become less stressful.

For startups, this structure attracts partners and investors. Clear processes signal maturity. Makers show readiness without sacrificing agility.

Responsible scaling protects reputation. Customers receive consistent products. Support teams troubleshoot faster and automation supports growth without chaos.

Conclusion: The Practical Future Of Automation In Making

Automation has reshaped how makers approach hardware development. The change did not happen overnight. It grew from practical needs and accessible tools.

Makers use automation to reduce errors, speed iteration, and support quality. They combine machines with human judgment. That balance defines modern hardware work.

Automated welding robotics for tech manufacturing and software platforms now support teams of all sizes. A digital client management portal for consultants improves collaboration across boundaries. These tools connect people instead of isolating them.

The future of making looks structured yet creative. Automation gives makers room to think, test, and improve. Hardware development becomes clearer, steadier, and more collaborative. Makers stay in control while letting machines handle the repeatable work.