Diffractive optical lenses are special lenses that function based on the principle of diffraction. Like normal, traditional lenses, diffractive optical lenses also focus the input light beams onto a focal plane. However, in contrast to conventional lenses, a diffractive optical lens exploits the light beam’s wave nature. On the other hand, conventional lenses create a focal spot by using only the principle of light refraction. The refractive element’s curvature is calculated in a way that results in the local bending of a collimated light beam towards a focal point.

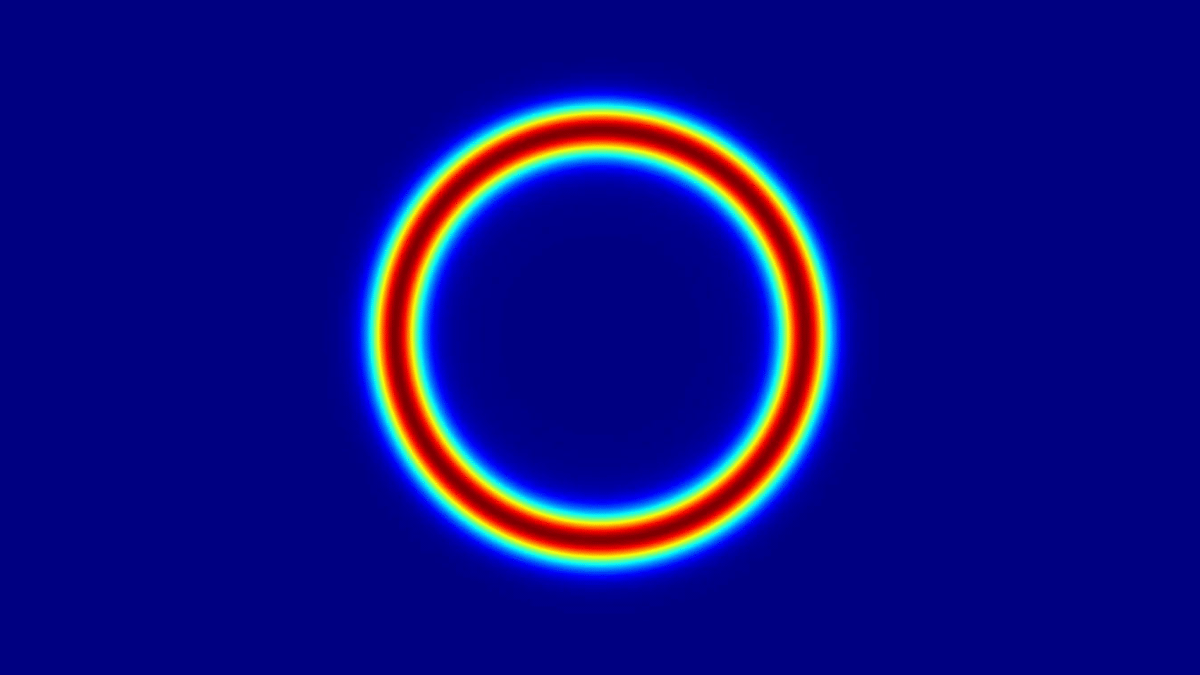

The thickness of the lens is inversely proportional to the distance of the focal length. Whereas, diffractive optical lenses are usually very thin. The surface of a diffractive optical lens consists of tiny pixels or modulating elements with an encoded equivalent radius of curvature. The encoding process is quite similar to that of a refractive lens. The focusing function along with the curvature calculation is encoded into a transparent substrate. Diffractive optical lenses are called Fresnel zone plates.

It is important to adjust the curvature profile or the shape of the lens surface to match the height of a single light wavelength. The lens shape includes multiple small sections or sampled in the spatial directions. Then they get simplified into discrete phase steps. Materials, such as glass and plastic can emboss the discrete phase steps. This is a common method for producing all diffractive optical elements. This process will help to generate a thin, lightweight optical element that can focus light beams and form images. The manufacturing processes of these optical elements make them less sensitive to changes in focal length due to temperature differences.

In comparison to a conventional lens, a diffractive optical lens brings multiple advantages. The compactness and lightweight of diffractive optical lenses make these lenses appropriate for micro-optical systems. They are also efficient for high laser power applications since the laser damage control coating must function exclusively at normal incidence.

Diffractive optical lenses are useful for miniaturization and weight-sensitive applications. These lenses are crucial for

- Collimating light beams in fibre optic arrays,

- In applications that involve structured light using VCSELs or laser diode arrays, and

- In high-power laser applications using athermal lenses.

The diffractive effects result in higher spectral dispersion than refractive effects. However, the dispersion caused by these two effects works in opposite ways. We can balance the total dispersion on an optical system by combining conventional and diffractive lenses.

The compactness, lightweight, and efficiency of diffractive optical lenses make them suitable for numerous advanced laser applications. These lenses offer several advantages over conventional lenses. Diffractive optical lenses can endure high-power laser applications. These lenses are also useful in counteracting the chromatic dispersion effects in conventional lens systems.