Are you facing the vice of expensive and regular painting of metal items? Traditional practices can be maddening and yield low results. Lack of thoroughness and elaborate procedures result in disappointing outcomes.

No worries. Here is a solution. That is electrostatic spray painting.

When comparing electrostatic painting vs powder coating, electrostatic painting is as quick, precise, and economically viable as possible. It uses an electrical charge to produce a much better flat surface and improves durability. Moreover, it’s effective on handrails, fences, and many other structures, applying a long-lasting layer of protection, and eliminating costs for maintenance.

Are you curious to learn more about how electrostatic painting might help your property? This guide will help you do just that.

What Is Electrostatic Spray Painting?

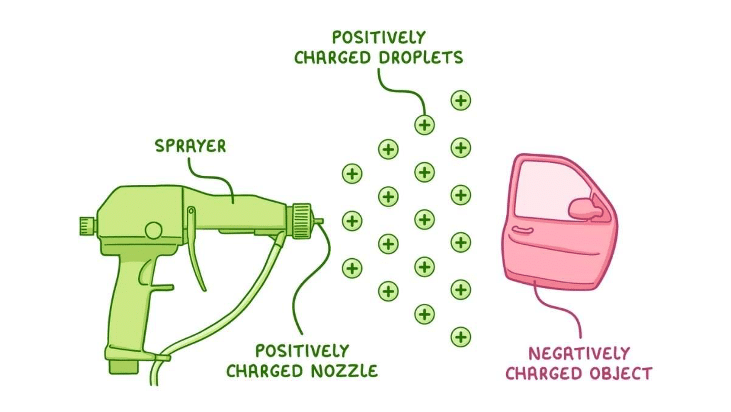

Electrostatic spray painting has the charge of electricity in depositing the painting to the alloys and plastics. This technique relies on the principle that opposites attract. By charging the object negatively and the paintpositively the paint is drawn towards the surface resulting in a tough and smooth paint coat.

You’ll likely experience static electricity by touching a metal object after rubbing against a carpet because the friction builds up an electrical charge in the body. That is why, when touching a grounded metal, the charge discharges, and the shock is felt.

An electrostatic field works in the same way as a magnetic field. Those with opposite charges will always cling to one another. A negatively charged object comprises more electrons than it should, while a positively charged object contains fewer electrons. Electrostatic painting is based on the attraction of opposite charges.

How Does an Electrostatic Spray Painter Function?

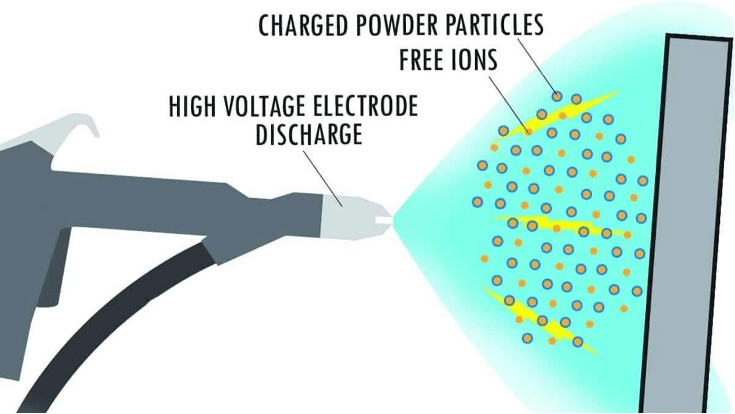

Electrostatic Spraying Mechanism

Note: You can take a look at a video of electrostatic Spray Here!

The electrostatic painting process paints the articles evenly with an electrical charge. The object to be painted is allowed to have a negative charge, the paint on its part will have a positive charge. This setup causes the paint to be attracted to the object like a magnetic attraction. A revolving nozzle sprays the positively charged paint on the surface uniformly and efficiently.

Effect of Electrostatic Painting

Charge Distribution In Electrostatic Painting

The general working of electrostatic spray painting is based on the law of attraction of opposite poles. The negative charge applied to the item attracts positively charged paint particles to the surface of the same item. Because when the paint is sprayed, it covers the whole object’s body and encases the object, including its back and contours. This makes it possible to leave no part of the object un-painted because the pattern covers each angle systematically.

Advantages of Electrostatic Painting: No Overspray

Uniform Electrostatic Spray

The key advantage of electrostatic painting is the reduction of overspraying. There’s a strong force of attraction between the positive and negative charges that make sure that the paint forms a good contact with the object and a little paint evaporates into the air. Particularly, it’s beneficial when you’re working on intricate shapes and multiple sides, as the paint will reach all surfaces without causing a mess.

Practical Example: Painting a Wrought Iron Fence

To depict the electrostatic painting process, let us look at a wrought iron fence painting.

As the electrostatic sprayer applies the paint, it evenly coats the fence, including hard-to-reach areas like the back and unreachable areas. The paint is attracted directly to the fence, with no paint dilution in the surrounding area and paint all over it. This process significantly minimizes waste and mess since all fence areas receive an even layer of paint without overspray.

Application of Electrostatic Painting in Commercial and Industrial Pros

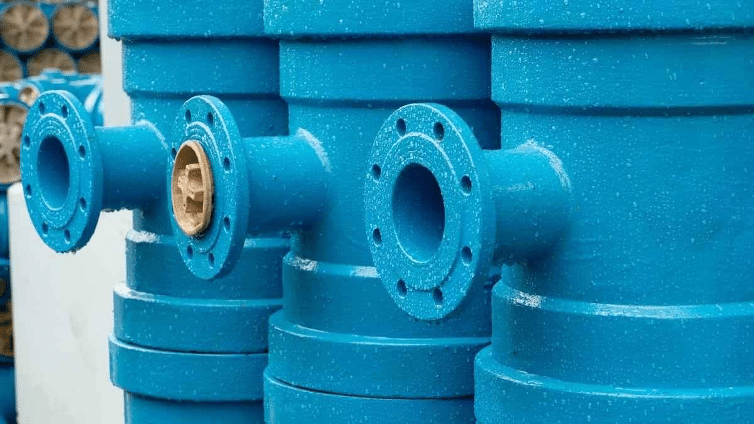

Industrial Pipelines Coating

Electrostatic painting is most applicable in business premises; offices, and shopping malls. It is applied on metal works like rails and doors among others. Moreover, it produces a fine finish with no overspray, thus causing no interruption and cleaning.

In factories and industries, it offers a hard-wearing skin that shields machinery from abrasion, corrosion, and unfavorable climates. The process guarantees full protection, increases the durability of machinery as well as decreases the overall expense of maintenance.

Electrostatic Painting Vs Powder Painting: A Detailed Comparison

Electrostatic Painting

Electrostatic painting applies paint through an electrostatic charge and gives coverage in all areas, even if it’s hard to reach. The method eliminates over-spray, giving a more uniform and consistent finish with minimal waste material waste. It is especially suitable for metallic material and complex shape work pieces due to its excellent adhesion and smooth finish.

Powder Coating

Powder Coated Parts

In contrast, traditional powder coating applies paint on the surfaces manually by use of brushes, rollers, or even aerosol. The approach tends to give an irregular outlook; the missed areas are touched up later on.

In the process, overspray often produces higher levels of unwanted paint and a less clean working area. In general, the result depends on the technique used and takes more time to apply and remove it.

Surfaces Ideal for Electrostatic Painting Vs Powder Coating

Electrostatic Painting

Electrostatic painting can be used on almost any part of a building system and might work well on exterior and interior architectural metals.

Yet some materials are better suited to be necessarily enriched by applying painting because of their advantages in terms of time and accuracy. It is most helpful for metal entrance canopies, stairs with balustrades, and other vaccinations of metal structures that are difficult to paint through normal means. Moreover, filing cabinets working in active offices can be painted without rearranging items in the cabinet.

Common items that are electrostatically painted include:

- A shopfront framework and doors

- Signage and roller shutters

- Curtain wall sections

- Aluminum doors and frames

- Lift doors

- Staircases

- Office furniture

Powder Coating

Powder coating uses a powder product to be sprayed to the surface through electrostatic charges, and solidified by heat to set a hard-wearing coat. The custom powder coating is best suited for items that require a thick, durable, and high-quality finish.

Ideally, powder coating colors are applied to surfaces including:

- Automotive Parts

- Outdoor Equipment

- Appliance Frames

- Industrial Machinery

Summary – Electrostatic Painting Vs Powder Coating

In comparing Electrostatic Painting vs Powder Coating is a quick, economical way to paint metallic parts. It allows uniform application as it effectively eliminates overspray and produces long-lasting coatings.

The technique is perfect for business and industrial use, is affordable, and provides excellent finishes on delicate micro designs on metals, machines, and furniture. Moreover, the process not only saves time and effort but also reduces wastage and makes the painted items last a long time. That is why it is preferred over other conventional methods of painting.

FAQs – Electrostatic Painting Vs Powder Coating

Q1. Can electrostatic painting be used on all types of metal surfaces?

Yes, electrostatic painting can precisely be applied on most metal surfaces, including steel, aluminum, and iron.

Q2. Is electrostatic painting more expensive than traditional painting?

While the initial setup for electrostatic painting may be higher, however, the long-term benefits, such as reduced material waste and less frequent touch-ups, make it a cost-effective choice.

Q3. How long does it take for electrostatic paint to dry?

Drying time can vary depending on the type of paint used. In general electrostatic coatings typically dry faster than traditional paint due to their even application.

Q4. Can electrostatic painting be done indoors?

Yes, electrostatic painting can be performed indoors. Because, it produces minimal mess and needs minimal overspray, making it ideal for office furniture, filing cabinets, and other indoor items.

Q5. What are the benefits of electrostatic painting vs powder coating?

Electrostatic painting provides even coverage, reduced overspray, better durability, and lower material waste than traditional powder coating methods, making it a more efficient and long-lasting solution.